Concrete blocks are a hot commodity in the construction industry. Their popularity stems from their durability and versatility. They can be used in a number of different applications, ranging from landscaping to construction. Because they are made out of concrete, they are strong enough to take a beating without sustaining any damage. They also hold up well in just about any type of weather. As an added bonus, they are also affordable to purchase, which is why many people use them in their projects.

Manufacturing and selling concrete blocks can be a profitable business model. Because the blocks are so popular, there are a lot of potential customers out there. If you decide to start a business of fully automatic concrete block making machine, you shouldn’t have any trouble finding people to buy them.

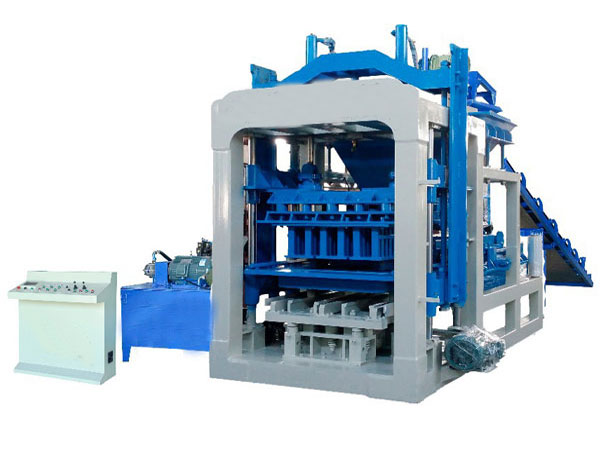

The best way to get your business up and running is by investing in a fully automatic block making machine. There are a lot of benefits associated with using one of these machines rather than making the blocks manually.

One of the biggest benefits is that there is a lot less labor involved. The process of making the blocks is fully automated from the time that the concrete is mixed until the finished blocks come off of the production line.

Most of these machine made bricks bangladesh have hoppers that are filled with different types of aggregate. A loader places a different aggregate in each hopper. The machine automatically measures the correct amount of each aggregate, adding it to the mixer. A precisely measured amount of water is then added to the mixer and the concrete is thoroughly mixed.

A special conveyor system is then used to transport the wet concrete to another hopper. From there it is placed into the molds. After the molding process is complete, the blocks are then removed from the system by a forklift and taken to a special area where they can cure.

The only time there is manual labor involved in the process is at the very beginning when the loader adds the aggregate to the hoppers and at the very end when the forklift takes the completed blocks away to cure. That means that only a couple of workers are required to manage the entire process. This helps keep the cost of labor extremely low.

Since all of the heavy lifting and mixing is done by the machine, you don’t have to worry about workers getting fatigued. With a manual cement block machine, frequent breaks are required so that the workers have a chance to rest and regain their strength. Automatic machines, on the other hand, can operate continuously without a break, dramatically increasing their output capacity.

Investing in a fully automatic block making machine makes sense. Not only do these machines require very little manual labor but they also are capable of producing a large number of concrete blocks in a short amount of time. By reducing your labor costs and increasing your production output, one of these machines can allow you to earn far more profit with your block making business. Get business start from Aimix web page: https://aimixbangladesh.com/automatic-brick-making-machine/.