As fly ash bricks become more and more common in projects around the world, the demand for these bricks continues to rise. Fly ash bricks have special features that make them quite useful in certain construction scenarios. As many new construction projects being undertaken throughout the world become increasingly complex, the need for these bricks sees a steady rise. Because of this, it’s important that those in construction gain a better understanding of the features of a semi automatic fly ash bricks making machine for sale.

Note Design And Specifications

When it comes to ash brick machines, many construction professionals wonder about its design and specifications. Many people that have dealt with fly ash bricks understand that it’s a brick that is certainly much harder to produce than regular bricks. There are a lot more processes involved in the manufacture of a fly ash brick than most other commonly used bricks. Hence, the curiosity often leads to questions regarding all of the different features a given brick making machine may exhibit.

Choose Automatic Or Semi Automatic Type

First of all, most of the most popular fly ash brick making machines are semi automatic. What this means is that there is an automatic function to the brick making machine, that needs to be supported by manual inputs. Indeed, the entire process of making these machines has yet to be completely automated. Because of this, any business that is interested in investing in this type of brick making machine must be willing to hire more labor so that they can have the machine work at full capacity. You can learn more about cost of fully automatic fly ash brick making machine.

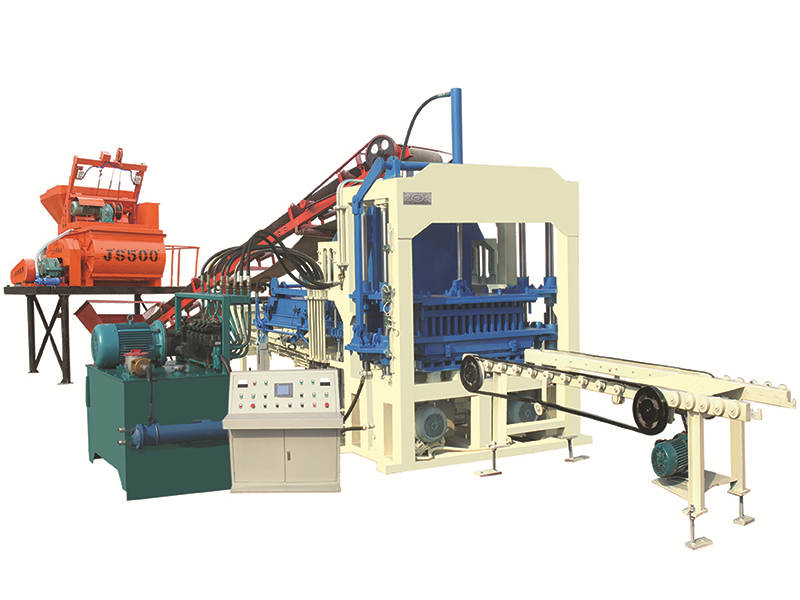

In addition to the semi automatic capabilities of fly ash brick making machines, they are also quite large. As mentioned, there are a lot more processes involved in making fly ash bricks than your average brick. Because of this, there is a larger and more powerful required to produce these bricks. Lots of managers already complain about the huge amount of space regular brick making machines use. When it comes to fly ash making machine, the amount of space that they take up is much higher than regular brick making machines. Thus management has to be prepared to possibly lease a larger amount of space to get the machines properly installed.

Costs Of Semi Automatic Fly Ash Brick Machine

The costs of semi automatic ash brick making machines are higher than regular brick making machines. The reasoning behind the increased costs is fairly easy to understand. Due to the fact that fly ash bricks require more process to manufacture, as well as more space to facilitate manufacturing, the fly ash brick machines will cost a lot more than regular brick making machines. Hence, it is important for professionals to know that in addition to the increased space requirements of these machines, there is an increased amount of capital required to procure them.

All in all, having in-house manufacturing of fly ash bricks through the use of ash brick machine may be greatly beneficial for a business. However, it’s important for construction managers to understand all of the implications that come with such a resource-heavy machine such as fly ash brick making machine.