In the fast-paced world of manufacturing and logistics, efficiency, safety, and technological advancement are key drivers of success. Overhead bridge cranes have long been integral to material handling, providing the ability to lift and move heavy loads with precision and reliability. As industries evolve, so too do the innovations surrounding these cranes, enhancing their capabilities and adapting them to meet the demands of modern operations. This article explores the future of material handling through innovations in overhead bridge cranes for sale, highlighting trends that are shaping the industry.

The Shift Toward Automation

One of the most significant trends in overhead bridge crane technology is the shift towards automation. Automated overhead cranes are increasingly being integrated into production lines, warehouse systems, and logistics operations, streamlining material handling processes.

- Robotics Integration: The combination of robotics and overhead cranes allows for precise movements and reduced labor costs. Automated cranes can operate with minimal human intervention, ensuring that heavy loads are handled efficiently and safely. This integration is particularly beneficial in environments where repetitive lifting tasks can lead to fatigue and increased risk of injury.

- Smart Control Systems: Advanced control systems equipped with sensors and machine learning algorithms enable cranes to adapt to varying load conditions and optimize their movements. These smart systems can enhance productivity by reducing cycle times and minimizing unnecessary movements, ultimately leading to significant time and cost savings.

Internet of Things (IoT) and Connectivity

The advent of the Internet of Things (IoT) is transforming the way overhead bridge cranes, including single girder and double girder bridge cranes, operate and are managed. By integrating IoT technology, cranes can become part of a connected ecosystem that enhances monitoring, maintenance, and operational efficiency.

- Real-Time Monitoring: IoT-enabled cranes can provide real-time data on their performance, load conditions, and operational metrics. This data can be accessed remotely, allowing operators to monitor crane operations from anywhere, improving response times to potential issues and ensuring optimal performance.

- Predictive Maintenance: By analyzing data collected from sensors, companies can predict when a crane requires maintenance before issues arise. Predictive maintenance reduces downtime and repair costs, as potential failures can be addressed proactively rather than reactively. This capability is particularly valuable for businesses seeking to minimize operational disruptions.

Enhanced Safety Features

Safety has always been a top priority in material handling, and innovations in overhead bridge cranes are increasingly focused on enhancing safety protocols. Modern cranes are now equipped with advanced safety features designed to protect operators and workers in the vicinity.

- Load Monitoring Systems: Many new overhead bridge cranes come with integrated load monitoring systems that provide real-time feedback on the weight of the load being lifted. These systems help prevent overloading, reducing the risk of accidents and equipment damage.

- Collision Avoidance Technologies: As cranes operate in busy environments, the risk of collisions with other equipment or structures can increase. Advanced collision avoidance systems use sensors and cameras to detect obstacles and automatically adjust the crane’s movements, ensuring safer operation.

- Operator Training Simulators: Virtual reality (VR) and augmented reality (AR) technologies are being used to train crane operators in a simulated environment. These training programs can enhance operators’ skills, improving safety and efficiency without putting anyone at risk during the learning process.

Sustainability and Energy Efficiency

As businesses increasingly focus on sustainability, innovations in overhead bridge cranes are also addressing energy efficiency and environmental impact.

- Energy-Efficient Motors: Newer models of overhead bridge cranes feature energy-efficient motors that consume less power during operation. This not only reduces operating costs but also aligns with sustainability goals by minimizing energy consumption.

- Regenerative Braking Systems: Similar to electric vehicles, some overhead cranes are now equipped with regenerative braking systems that recover energy during the braking process. This energy can be redirected back into the power system, enhancing overall energy efficiency. When you are looking for an overhead crane for your lifting needs, it is very important to cooperate with a reliable crane manufacturer for a quality crane machine to ensure safe lifting work.

Customization and Modular Design

The future of overhead bridge cranes also lies in their ability to be customized and adapted to specific operational needs. Manufacturers are increasingly offering modular designs that allow businesses to configure cranes according to their unique requirements.

- Modular Components: Modular cranes can be easily expanded or reconfigured as operational needs change. This flexibility ensures that companies can adapt their material handling systems without the need for a complete overhaul, saving both time and resources.

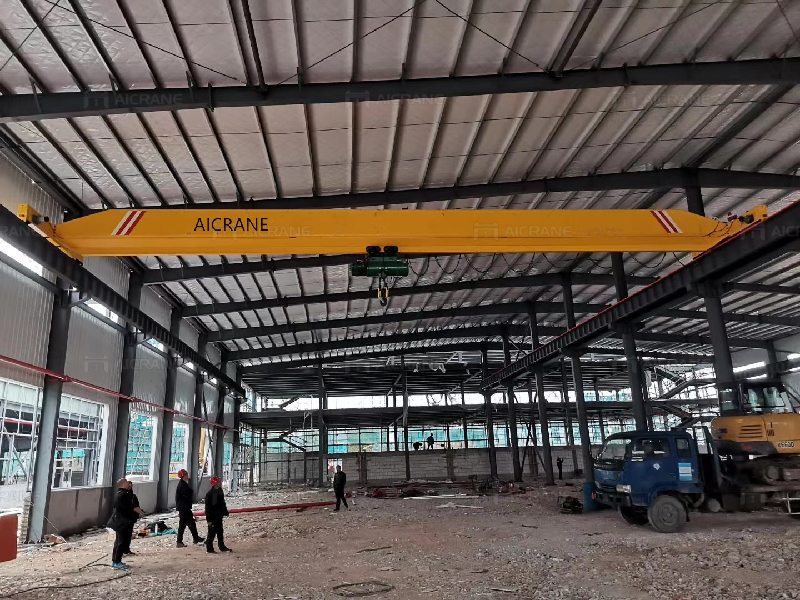

- Tailored Solutions: Many manufacturers are now offering customized solutions that take into account the specific challenges faced by different industries. From specialized attachments to tailored control systems, these innovations enable companies to maximize the utility of their overhead bridge cranes. For a customized crane machine, you are suggested to contact Aicrane Group for a suitable one.

Conclusion

The future of material handling is being shaped by a wave of innovations in overhead bridge cranes, driven by automation, IoT integration, enhanced safety features, sustainability, and customization. As these cranes continue to evolve, they offer businesses new opportunities to improve efficiency, safety, and productivity.

Investing in innovative overhead bridge cranes not only helps companies streamline their operations but also positions them for success in an increasingly competitive landscape. By staying informed about the latest trends and technologies, businesses can make strategic decisions that enhance their material handling capabilities and drive growth in the years to come. As the industry continues to adapt, the overhead bridge crane will remain a vital tool in the quest for operational excellence.