Purchasing a container crane is a significant investment, and understanding the factors that influence its price can help you make an informed decision. Container crane price varies based on numerous elements such as the crane’s type, size, specifications, and additional features. By exploring these factors, you can assess your project needs and negotiate a reasonable deal with manufacturers or suppliers. Below are the key factors influencing container crane pricing.

Type of Container Crane

Container cranes come in various types, each designed for specific applications. The type you choose plays a crucial role in determining the price:

Rubber-Tyred Gantry (RTG) Cranes: These RTG cranes are mobile cranes used in ports or container yards. Their mobility and versatility generally make them more expensive than fixed cranes.

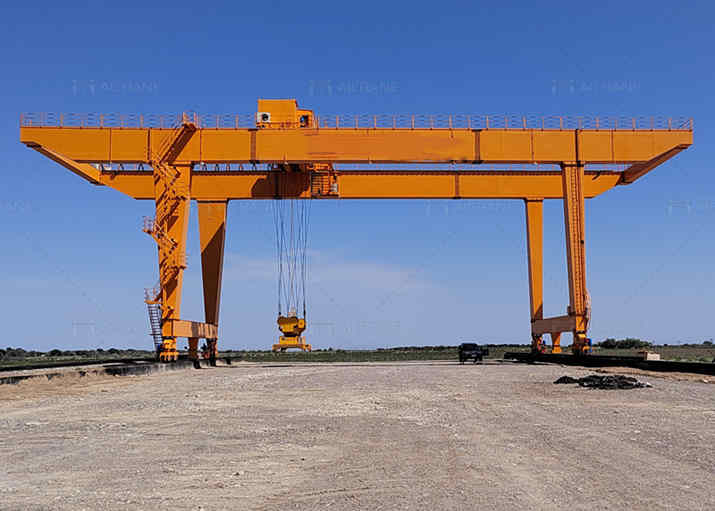

Rail-Mounted Gantry (RMG) Cranes: Fixed and running on tracks, RMG cranes are suitable for large-scale container handling in confined areas. Their price is influenced by track installation and operational range.

Ship-to-Shore (STS) Cranes: Specifically designed to load and unload containers from ships, STS cranes are the most expensive due to their size, lifting capacity, and high operational efficiency.

Each type has unique features that cater to different project needs, and the more specialized the crane, the higher the price tends to be.

Lifting Capacity

The lifting capacity of a container crane determines its ability to handle heavy containers. Cranes with higher lifting capacities (e.g., 40 tons or more) require more robust materials, larger motors, and advanced technology, which significantly impact their cost.

Low-Capacity Cranes: Suitable for small or medium-sized container yards. They are more affordable but limited in scope.

High-Capacity Cranes: Necessary for large ports handling massive cargo volumes. These cranes are more expensive due to their increased structural and mechanical demands.

Assess your project’s container weight requirements to balance cost and efficiency.

Span and Height Requirements

The span of a crane refers to the width it covers, while the height requirement refers to its ability to stack containers vertically. Larger spans and greater heights require additional materials and engineering expertise, raising the overall price.

Wide-Span Cranes: Suitable for handling multiple rows of containers simultaneously. They require reinforced structures and high-performance motors.

Tall Cranes: Used for vertical stacking in container yards with limited horizontal space. Increased height often necessitates advanced safety features and stronger components.

Accurately estimating your space and stacking needs ensures you invest in the right crane size without overpaying for unnecessary specifications.

Material Quality

The materials used in the construction of a container crane impact both its performance and cost. High-quality materials, such as high-strength steel, are essential for durability and reliability but come at a premium price.

Corrosion Resistance: Cranes used in coastal areas must be made with materials resistant to saltwater corrosion, increasing the cost.

Weather Resistance: If your crane operates in extreme climates, additional coatings or weatherproofing measures may be required.

While opting for cheaper materials might seem cost-effective initially, it can lead to higher maintenance expenses and shorter crane lifespans.

Technological Features

Modern container cranes often incorporate advanced technology to enhance efficiency and safety, but these features come with a higher price tag.

Automation: Automated cranes require sophisticated control systems and sensors for precision handling, adding to their cost.

Remote Operation: Remote-controlled cranes reduce labor costs but involve significant upfront investment in technology.

Energy Efficiency: Energy-saving systems, such as hybrid or electric-powered cranes, may increase the initial price but result in long-term operational savings.

Evaluate whether advanced features align with your operational needs to determine if the additional investment is worthwhile.

Customization Requirements

If your project demands specific customizations, such as unique dimensions, colors, or special safety features, the price of your container crane will increase. Custom designs require additional engineering work and may delay delivery times.

Industry-Specific Needs: Cranes tailored for unique industries, such as intermodal or offshore operations, often cost more.

Optional Add-Ons: Features like anti-sway systems, advanced monitoring tools, or specialized hooks can drive up the price.

Ensure your customizations are essential to avoid unnecessary cost inflation.

Manufacturer’s Brand and Reputation

The manufacturer you choose significantly influences the container crane price. Established brands with a proven track record for quality and service typically charge more.

Reputable Manufacturers: They offer higher quality assurance, better warranties, and reliable after-sales support, which justify their premium pricing.

Lesser-Known Brands: These may provide lower-cost cranes but often lack comprehensive support or long-term reliability.

It’s crucial to balance quality and budget by thoroughly researching manufacturers like Aicrane and their products.

Logistics and Installation Costs

The location of your project and the installation process impact the total cost of acquiring a container crane.

Transportation: Larger cranes require specialized transportation, which adds to the logistics cost.

Site Preparation: Installation may involve significant site preparation, such as building tracks for RMG cranes or strengthening foundations for STS cranes.

Assembly: Some cranes require on-site assembly by skilled technicians, increasing labor costs.

Factor in these costs when budgeting for your container crane purchase.

After-Sales Services

Additional services, such as maintenance packages, warranties, and training, can influence the overall price.

Comprehensive Warranties: A longer warranty period usually reflects the manufacturer’s confidence in their product but may add to the price.

Training and Support: Training crane operators and maintaining the equipment can incur additional costs.

Investing in good after-sales services can save money in the long run by ensuring smooth operations and minimizing downtime.

Understanding the factors influencing container crane price allows you to make informed purchasing decisions tailored to your project needs. Consider the type of crane, lifting capacity, span, material quality, technological features, customization, manufacturer reputation, logistics, and after-sales services. By balancing these factors, you can find a container crane that fits your requirements and budget efficiently.

Research thoroughly, consult with reputable manufacturers, and don’t hesitate to negotiate for the best deal. This comprehensive approach ensures that your investment in a container crane yields optimal value and performance.