An Asphalt Mixing Plant is a machine that is used to make asphalt or other kinds of coated roadstone. Coated roadstone is also known as asphalt concrete and is an essential compound in road constructions. Asphalt is made by mixing several materials such as sand, aggregates, and stone dust in their right proportions. The mixture is then heated and coated with a binder compound. The binder compound can either be tar or bitumen based. On the other hand, mobile asphalt mixing plant is a portable plant that can move from one point to another.

Main Types of Mobile Asphalt Mixing Plants

Asphalt mixing plants are broadly categorized into two:

– Mobile Asphalt Mixing Plants ( planta de asfalto movil )

– Stationary Asphalt Mixing Plants ( planta de aslfalto en venta )

1. Mobile Asphalt Mixing Plant

The portable asphalt plant is also called a mobile plant because it can be moved from one point to another to facilitate the construction activities. The mobile asphalt mixing plant is an excellent choice for medium-sized and small road construction activities. The plants can produce colored asphalt, asphalt, and modified asphalt.

2. Stationary Asphalt Mixing Plant

The stationary asphalt mixing plant is bigger and cannot be moved from one point to another. The plant is usually fixed on the sites of construction and cannot assure non-stop working. Since the stationary plant cannot be moved to a different location as the construction activities progress, construction activities slow down a bit, and this increases the production cost.

Plant part: aimixgrupo.com/silo-horizontal-para-cemento/

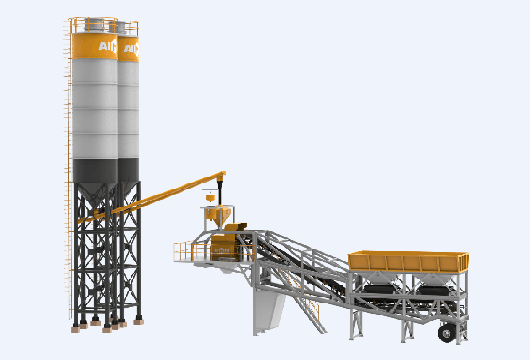

Essential Components of a Mobile Asphalt Mixing Plant

Portable asphalt plants have several components that work together to manufacture asphalt. These components are:

1. Wheels- The asphalt plant is mounted on wheels to ease locomotion from one point to another. The wheels help the plant move to different locations at the construction site where asphalt is required.

2. Supply System for Raw Materials- The plant has a strong structure that helps constructors pour raw materials into the manufacturing plant.

3. Bitumen Tanks- The bitumen tanks holds bitumen that is used during the asphalt manufacturing process.

4. Filler Silo- Filler silos are used to add filler materials to the asphalt during its manufacturing process.

5. Heating System- The system is composed of a heating burner that is used for drying and heating applications.

7. Vibration Screen- The screen is used to sort the aggregates of asphalt into different materials.

8. Hot Bin- The hot bin stores the aggregates used for the asphalt production process.

9. Mixer- The mixer is used to combine the asphalt ingredients through rotation and twisting movements.

10. Control System- Asphalt plants are composed of a computerized automatic control system that is responsible for monitoring and controlling the plant during the manufacturing process.

Features and Benefits of Mobile Asphalt Mixing Plant

– The plant can be installed quickly.

– Can work without a concrete foundation.

– Guarantees faster production of asphalt.

– Assures continuous production of asphalt.

– The design is flexible in construction.

– The mobile plant has low maintenance and running costs.

Applications of the Mobile Asphalt Mixing Plant

1. Road constructions

2. Airports

3. Ports and mining centers

4. Stadiums and sporting grounds

Precautions While Working With The Mobile Asphalt Mixing Plant

1. All the workers should have their safety gears on to prevent accidents and injuries ( lesiones ).

2. The mobile asphalt mixing plant should undergo periodic maintenance to guarantee operational efficiency and safety.

3. Exhaust gases from asphalt plants should be treated before being released into the environment to prevent air pollution.

4. Moving parts of the plant should be covered with guides to prevent accidents.

5. Only trained and qualified operators should run and maintain the plant.

6. Smoking should be prohibited around asphalt plants to prevent fire accidents from happening.

Choosing the Right Equipment for Your Project

While selecting the right plant to use for a particular project, check on the following:

1. The Cost of the Machine

The machine should be affordable and cost-effective.

2. The Size of the Project

Small projects are economical when portable asphalt plants are used. Large projects, on the other hand, are economical when fixed asphalt plants are used.

3. The Flexibility of the Plant

A flexible plant is cheaper than a fixed plant.

Where to Buy/ Manufacturers of Mobile Asphalt Mixing Plants

1. Speco Asphalt Batching Plant

2. LONTTO Asphalt Plants

3. LINNHOFF Asphalt Plant

4. Vinayak Asphalt Plant

5. Boral Asphalt Business Plant

Differences Between Various Designs

The following points state the differences that distinguish asphalt plants:

– Presence or absence of wheels.

– Size of the mixer unit.

– Type of control systems employed in the plant.

– The shape of the mixer chamber.

In a nutshell, understanding the various types of asphalt plants is critical because it helps you make the right decision when choosing the best, cost-effective, and economical asphalt design to employ for your construction work.