In the landscape of industrial operations, efficiency reigns supreme. Double Girder Overhead Cranes stand as stalwarts in the domain of material handling, offering robust lifting capabilities and precise maneuverability. Mastering the techniques for operating these cranes is pivotal for optimizing efficiency in industrial settings. In this article, we delve into the specialized techniques and strategies for maximizing efficiency in Double Girder Overhead Crane operations, including insights into overhead crane for sale and the utilization of 30-ton overhead cranes.

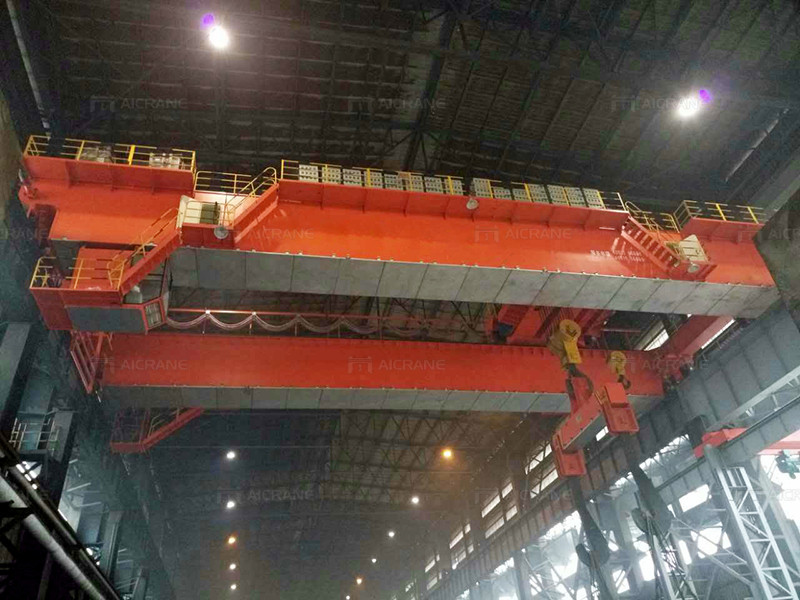

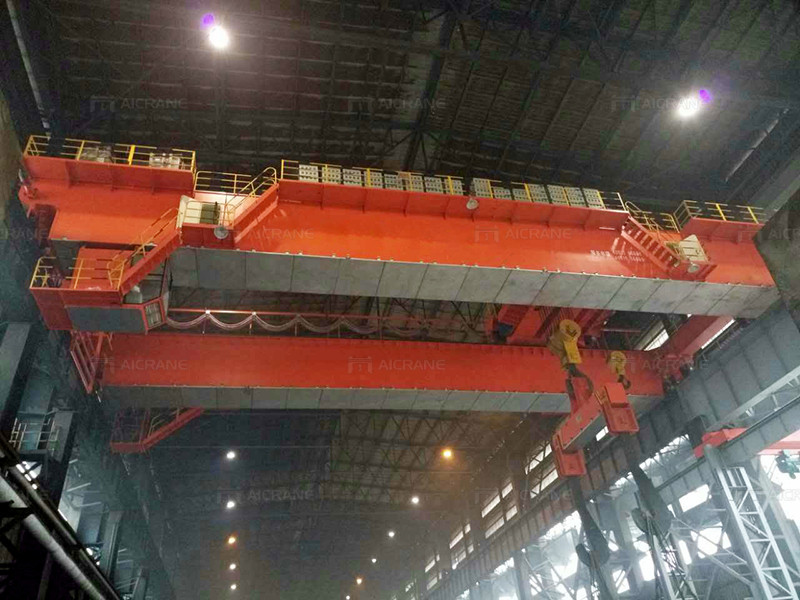

Understanding Double Girder Overhead Cranes

Double Girder Overhead Cranes are prominent fixtures in industrial facilities, renowned for their ability to handle heavy loads with precision and reliability. Unlike single girder cranes, double girder configurations provide increased stability and lifting capacity, making them ideal for lifting heavier loads and navigating challenging environments.

Proper Load Balancing

Maintaining optimal load balance is paramount for maximizing efficiency in Double Girder Overhead Crane operations. Operators must ensure that the load is evenly distributed across the crane’s lifting mechanism(Купить кран мостовой) to prevent overloading and instability. By properly balancing the load, operators can enhance safety and optimize crane performance.

Precise Control and Movement

Precision is key when operating Double Girder Overhead Cranes. Operators should execute movements with deliberate control, minimizing unnecessary stops and starts to streamline operations. By maintaining smooth and precise movements, operators can reduce cycle times and maximize productivity.

Utilization of Advanced Features

Modern Double Girder Overhead Cranes come equipped with advanced features and technologies designed to enhance efficiency and safety. These may include variable speed controls, anti-sway systems, and remote monitoring capabilities. By leveraging these advanced features, operators can optimize crane performance(Мостовой кран в цеху) and adapt to dynamic operational requirements.

Routine Maintenance and Inspections

Regular maintenance and inspections are essential for ensuring the continued efficiency and reliability of Double Girder Overhead Cranes. Operators should adhere to manufacturer-recommended maintenance schedules, performing routine checks on critical components such as hoists, trolleys, and structural elements. By proactively addressing maintenance issues, operators can minimize downtime and extend the lifespan of the crane.

Optimized Workspace Layout

Efficient workspace layout plays a crucial role in maximizing the efficiency of Double Girder Overhead Crane operations. Operators should strategically position materials, equipment, and workstations to minimize travel distances and optimize workflow. By optimizing the workspace layout, operators can reduce idle time and streamline material handling processes.

Insights into Overhead Crane for Sale

When considering the purchase of a Double Girder Overhead Crane, businesses should evaluate their specific operational requirements and select a crane that aligns with their needs. Factors to consider include lifting capacity, span length, and available features. Additionally, businesses should partner with reputable suppliers that offer quality products and reliable support services.

Utilization of 30-Ton Overhead Cranes

30-ton overhead cranes are well-suited for handling heavy loads in industrial applications such as manufacturing, construction, and shipping. These cranes offer robust lifting capabilities and can accommodate a wide range of materials and equipment. When selecting a 30-ton overhead crane(мостовой кран 30 т), businesses should ensure that it meets their specific lifting requirements and operational needs.

Implementing Training Programs

Investing in comprehensive training programs for crane operators is essential for mastering efficiency in Double Girder Overhead Crane operations. These programs should cover a range of topics, including crane operation techniques, safety protocols, equipment maintenance, and emergency procedures. By providing operators with the knowledge and skills they need to effectively operate Double Girder Overhead Cranes, businesses can improve efficiency, minimize downtime, and reduce the risk of accidents.